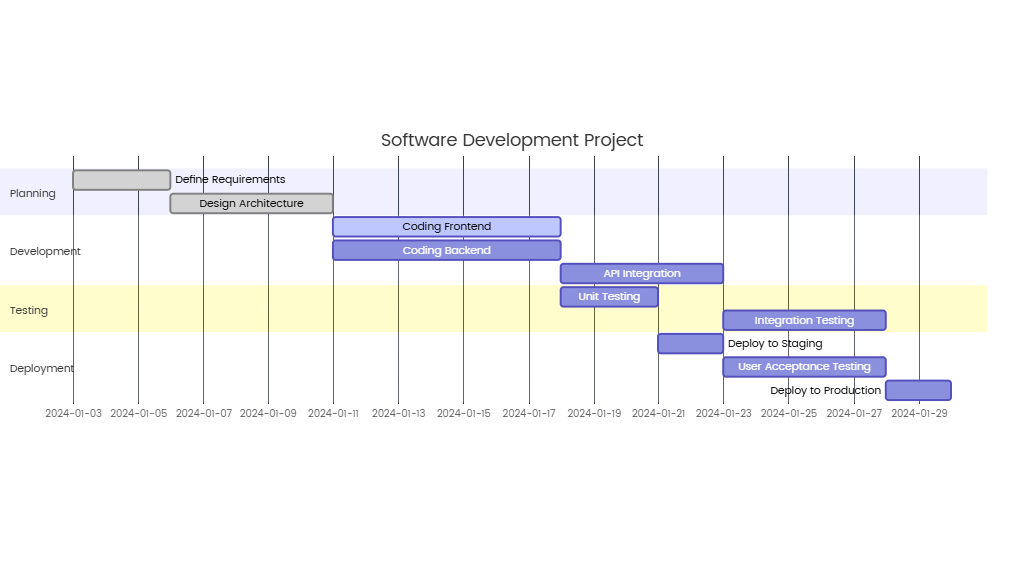

Gantt Chart for Construction Project: Managing Phases and Resource Allocation

Description

A Gantt chart is an essential visual tool for planning, executing, and monitoring construction projects, providing a structured timeline that integrates project phases, task dependencies, and resource allocation. This framework helps stakeholders—including contractors, engineers, and clients—coordinate activities, mitigate delays, and optimize resource use throughout the project lifecycle.

Core Components of the Construction Gantt Chart

- Timeline Structure

- Horizontal Axis: Represents the project duration, typically divided into weeks or months.

- Vertical Axis: Organizes tasks into hierarchical phases, subphases, and individual activities.

- Project Phases & Tasks

- Pre-Construction:

- Site assessment, permit acquisition, design finalization, and contract signing.

- Foundation Work:

- Excavation, soil stabilization, concrete pouring, and footing installation.

- Structural Construction:

- Framing (steel or wood), roofing, exterior wall installation, and structural inspections.

- MEP (Mechanical, Electrical, Plumbing):

- Installation of HVAC systems, electrical wiring, plumbing networks, and fire safety systems.

- Finishing Works:

- Interior 装修 (drywall, painting, flooring), exterior cladding, landscaping, and fixture installation.

- Finalization & Handover:

- Quality assurance checks, punch list resolution, final inspections, and client occupancy.

- Pre-Construction:

- Task Dependencies

- Critical Path: The sequence of tasks that directly impacts the project’s completion date (e.g., foundation must precede framing).

- Dependencies: Arrows indicate relationships (e.g., “Roofing” starts after “Structural Framing” finishes).

- Parallel Tasks: Activities that can occur simultaneously (e.g., MEP rough-ins alongside interior wall construction).

- Resource Allocation

- Labor: Crew sizes and skill sets (e.g., 10 masons for bricklaying, 5 electricians for wiring).

- Equipment: Scheduled use of cranes, excavators, or scaffolding, with downtime minimized.

- Materials: Delivery timelines for steel, concrete, and finishes (e.g., tiles arriving Week 20).

- Milestones

- Key checkpoints marked with symbols (e.g., ⚡ for “Groundbreaking,” ?️ for “Structural Completion,” ? for “Final Handover”).

Example Workflow & Timeline

PhaseTasksDurationDependenciesResourcesMilestone

Pre-Construction

Site survey, permit approval

Weeks 1–4

None

Survey team, legal team

Permits Approved ✅

Foundation

Excavation, concrete slab

Weeks 5–9

Permits Approved

Excavators, concrete crew

Foundation Complete ?️

Structural Framing

Steel beam erection, roof truss installation

Weeks 10–16

Foundation Complete

Crane, steelworkers

Framing Finished ?

MEP Installation

Electrical wiring, plumbing pipes

Weeks 17–24

Framing Finished

Electricians, plumbers

MEP Rough-Ins Done ?

Interior Finishes

Drywall, painting, flooring

Weeks 25–32

MEP Rough-Ins Done

Painters, carpenters

Finishes Completed ?

Final Inspections

Code compliance checks, punch list

Weeks 33–36

Finishes Completed

Inspectors, contractors

Occupancy Permit Granted ?️

Strategic Benefits

- Risk Mitigation

- Identifies bottlenecks (e.g., delayed material delivery) and allows proactive rescheduling.

- Example: Padding “Foundation” with a 2-week buffer for weather-related delays.

- Resource Efficiency

- Optimizes crew scheduling to avoid overworking teams (e.g., staggered MEP and finishing crews).

- Reduces equipment idle time by aligning machinery use with task sequences.

- Stakeholder Coordination

- Provides a shared visual reference for clients to track progress (e.g., “Exterior Cladding” completion by Week 20).

- Facilitates communication between subcontractors (e.g., ensuring plumbers and electricians coordinate pipe/wire routes).

- Cost Control

- Links tasks to budget lines (e.g., concrete costs in “Foundation” phase) for real-time financial tracking.

- Prevents rework by ensuring tasks follow the correct order (e.g., waterproofing before flooring).

Tools & Best Practices

- Software Tools: Procore, AutoCAD, Microsoft Project, or GanttPRO for advanced scheduling.

- Visual Customization: Color-code tasks by subcontractor (e.g., blue for electricians, orange for painters).

- Dynamic Updates: Regularly sync the chart with on-site progress using photos or daily reports.

- Contingency Planning: Include “buffer” tasks for high-risk activities (e.g., weather-dependent exterior work).