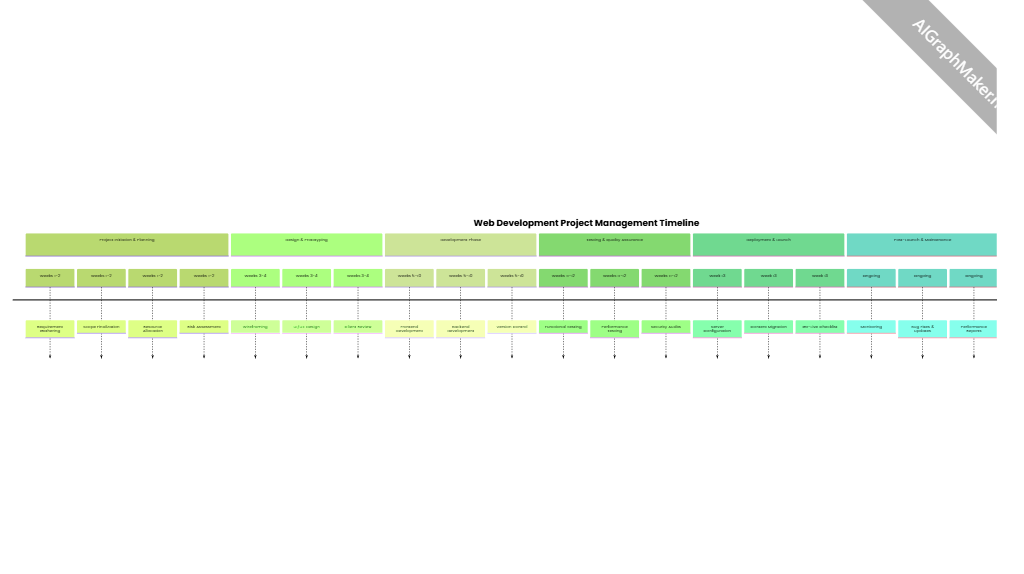

Here’s a detailed application of Gantt Charts in bridge construction process management, structured into key phases with technical insights from search results:

1. Project Planning & Task Breakdown

A Gantt Chart breaks down the bridge construction lifecycle into sequential tasks, aligning with industry best practices. For example:

Design Phase: Includes feasibility studies, structural design, and approvals (e.g., seismic compliance for typhoon-prone regions like the Philippines’ CCLEX project).

Procurement: Tracks material orders (e.g., steel, concrete) and equipment delivery timelines.

Construction Milestones: Defines critical stages like foundation work, viaduct assembly, and cable-stayed bridge installation.

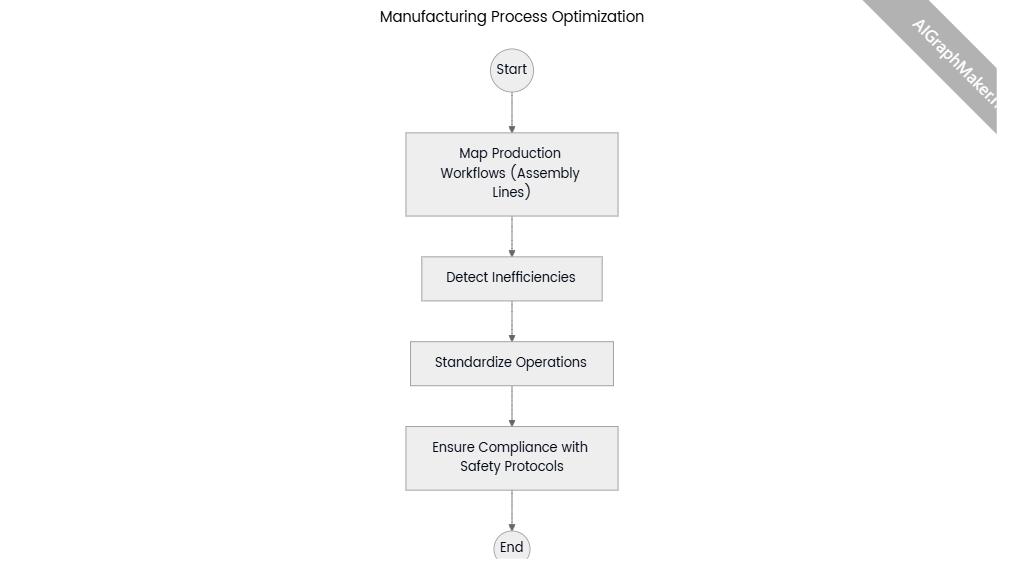

2. Resource Allocation & Dependency Mapping

Gantt Charts visualize resource dependencies to avoid bottlenecks:

Labor Coordination: Assigns teams to specific tasks (e.g., foundation specialists during initial phases, steelworkers during superstructure assembly).

Equipment Scheduling: Aligns crane usage with viaduct segment lifting to prevent overlaps.

Material Logistics: Tracks concrete pouring schedules to match curing times and avoid delays.

3. Progress Monitoring & Risk Mitigation

Real-time Gantt updates ensure alignment with timelines and highlight risks:

Seismic Compliance Checks: Flags delays in seismic-resistant design iterations (critical for regions like the Mactan Channel).

Weather Contingencies: Adjusts timelines for typhoon seasons (e.g., rescheduling outdoor tasks).

Quality Control Milestones: Tracks inspections (e.g., load testing for cable-stayed bridges) to meet safety standards.

4. Multi-Stakeholder Coordination

Gantt Charts enhance collaboration across disciplines:

Design-Construction Handoffs: Synchronizes approvals between engineers and contractors (e.g., viaduct-bridge joint design in CCLEX).

Regulatory Compliance: Maps deadlines for environmental impact assessments and permits.

Supplier Coordination: Aligns prefabricated component deliveries with on-site assembly phases.

5. Post-Construction & Documentation

Post-launch phases are tracked to ensure project closure:

Final Inspections: Schedules load tests and safety certifications.

Environmental Restoration: Tracks landscaping and debris removal post-construction.

Knowledge Transfer: Documents lessons learned for future projects (e.g., CCLEX’s digital collaboration model)

Description

Gantt Charts serve as a vital tool in bridge construction process management, providing a visual framework to orchestrate complex workflows, mitigate risks, and align multi-stakeholder efforts. Below is a detailed breakdown of their application across key phases, integrated with technical insights and real-world examples (e.g., the Philippines’ CCLEX project and Mactan Channel bridges):

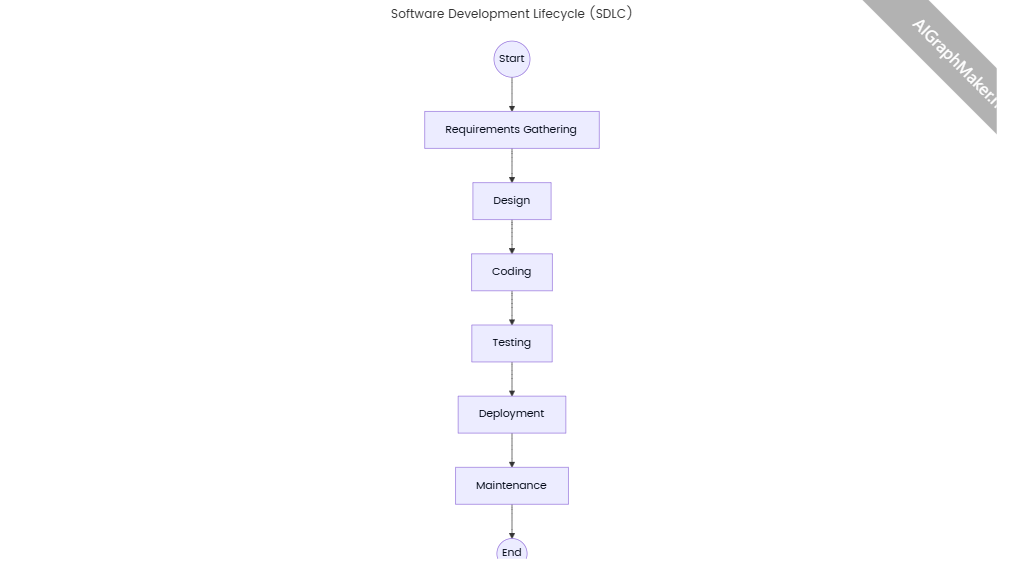

1. Project Planning & Task Breakdown

A Gantt Chart systematically decomposes the bridge construction lifecycle into sequential, actionable tasks, ensuring alignment with industry standards and regional requirements:

- Design Phase:

- Includes feasibility studies, structural engineering (e.g., seismic-resistant designs for typhoon-prone areas like CCLEX), and regulatory approvals.

- Example: In typhoon zones, timelines for seismic compliance reviews are prioritized to meet safety codes.

- Procurement:

- Tracks material orders (e.g., steel, high-strength concrete) and heavy equipment delivery (e.g., cranes, formwork) to prevent delays.

- Construction Milestones:

- Defines critical phases:

- Foundation Work: Piling, caisson installation, and soil stabilization.

- Superstructure Assembly: Viaduct segment erection, cable-stayed bridge component installation, and deck pouring.

2. Resource Allocation & Dependency Mapping

Gantt Charts visualize resource interdependencies to optimize workflows and eliminate bottlenecks:

- Labor Coordination:

- Assigns specialized teams to phases (e.g., foundation engineers in early stages, steel fabrication crews during superstructure assembly).

- Equipment Scheduling:

- Syncs crane availability with viaduct segment lifting or girder placement to avoid downtime.

- Material Logistics:

- Links concrete pouring schedules to curing times (e.g., 7-day curing periods for piers) and coordinates prefabricated component delivery (e.g., precast bridge sections) with on-site assembly.

3. Progress Monitoring & Risk Mitigation

Real-time Gantt updates enable proactive management of delays and hazards:

- Seismic & Structural Compliance:

- Flags delays in design iterations for earthquake-resistant features (e.g., base isolation systems in Mactan Channel bridges).

- Weather Contingencies:

- Builds buffer periods for typhoon seasons, rescheduling outdoor tasks (e.g., cable installation) during high-risk months.

- Quality Control:

- Schedules mandatory inspections (e.g., non-destructive testing for steel welds, load testing for cable-stayed spans) to ensure compliance with ASTM or AISC standards.

4. Multi-Stakeholder Coordination

Gantt Charts foster collaboration across engineers, contractors, regulators, and suppliers:

- Design-Construction Handoffs:

- Ensures seamless transitions (e.g., finalizing pier design before handing off to construction teams for CCLEX’s viaduct joints).

- Regulatory Compliance:

- Maps deadlines for environmental impact assessments (EIAs), wildlife protection measures, and permit renewals.

- Supplier Coordination:

- Aligns prefabricated component delivery (e.g., steel girders, bearings) with on-site milestones to avoid storage costs or delays.

5. Post-Construction & Documentation

The Gantt Chart extends into post-launch phases to ensure project closure and knowledge retention:

- Final Inspections:

- Schedules load tests, safety certifications (e.g., AASHTO standards), and compliance reviews with local authorities.

- Environmental Restoration:

- Tracks landscaping, riverbank rehabilitation, and debris removal to restore project sites.

- Knowledge Transfer:

- Documents lessons learned (e.g., CCLEX’s digital collaboration tools for real-time Gantt updates) for future projects, enhancing efficiency and risk management.

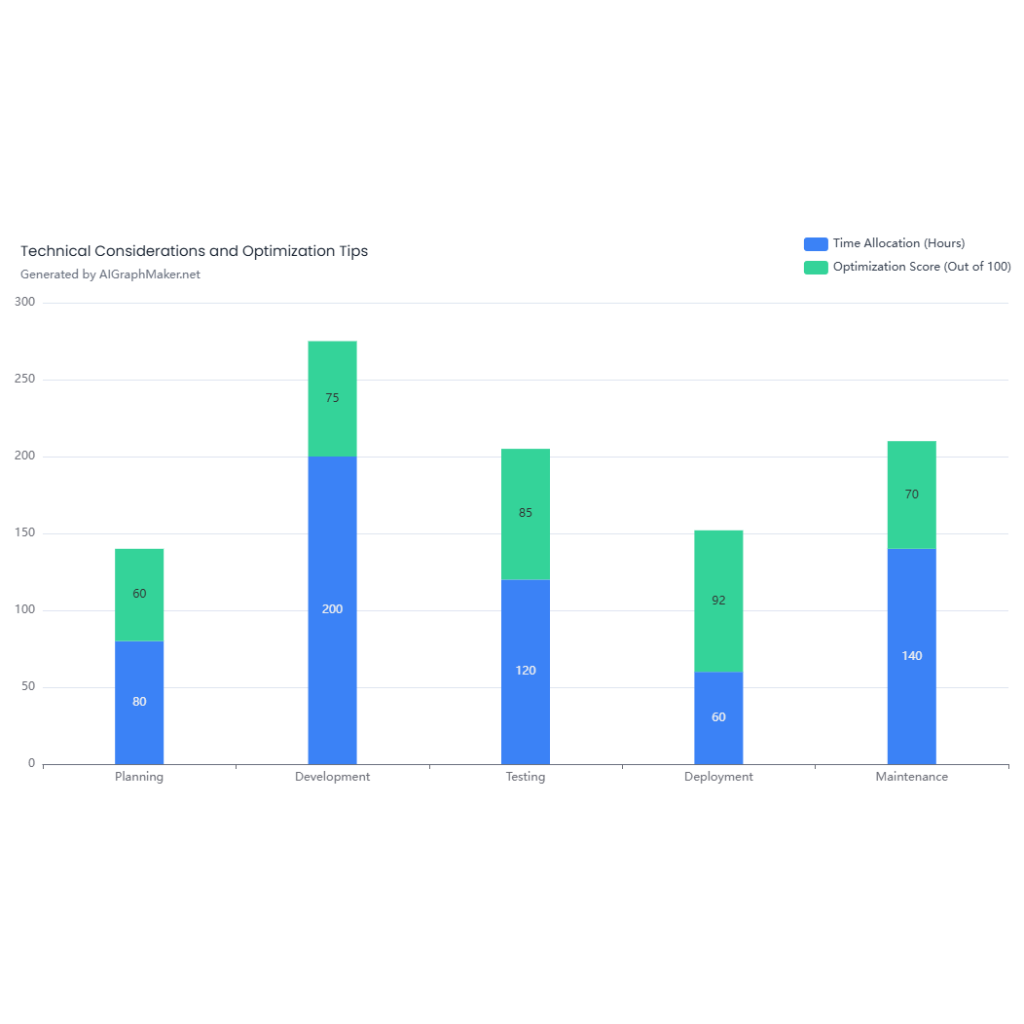

Key Benefits of Gantt Charts in Bridge Construction:

- Visual Clarity: Simplifies complex timelines for stakeholders at all levels.

- Risk Reduction: Proactively identifies delays in critical paths (e.g., material shortages, weather disruptions).

- Compliance Assurance: Ensures adherence to safety, environmental, and regulatory standards.

- Efficiency Gains: Optimizes resource use and minimizes costly rework through dependency mapping.

By integrating technical rigor with visual project management, Gantt Charts empower teams to deliver bridge projects on time, within budget, and to the highest safety and quality standards.